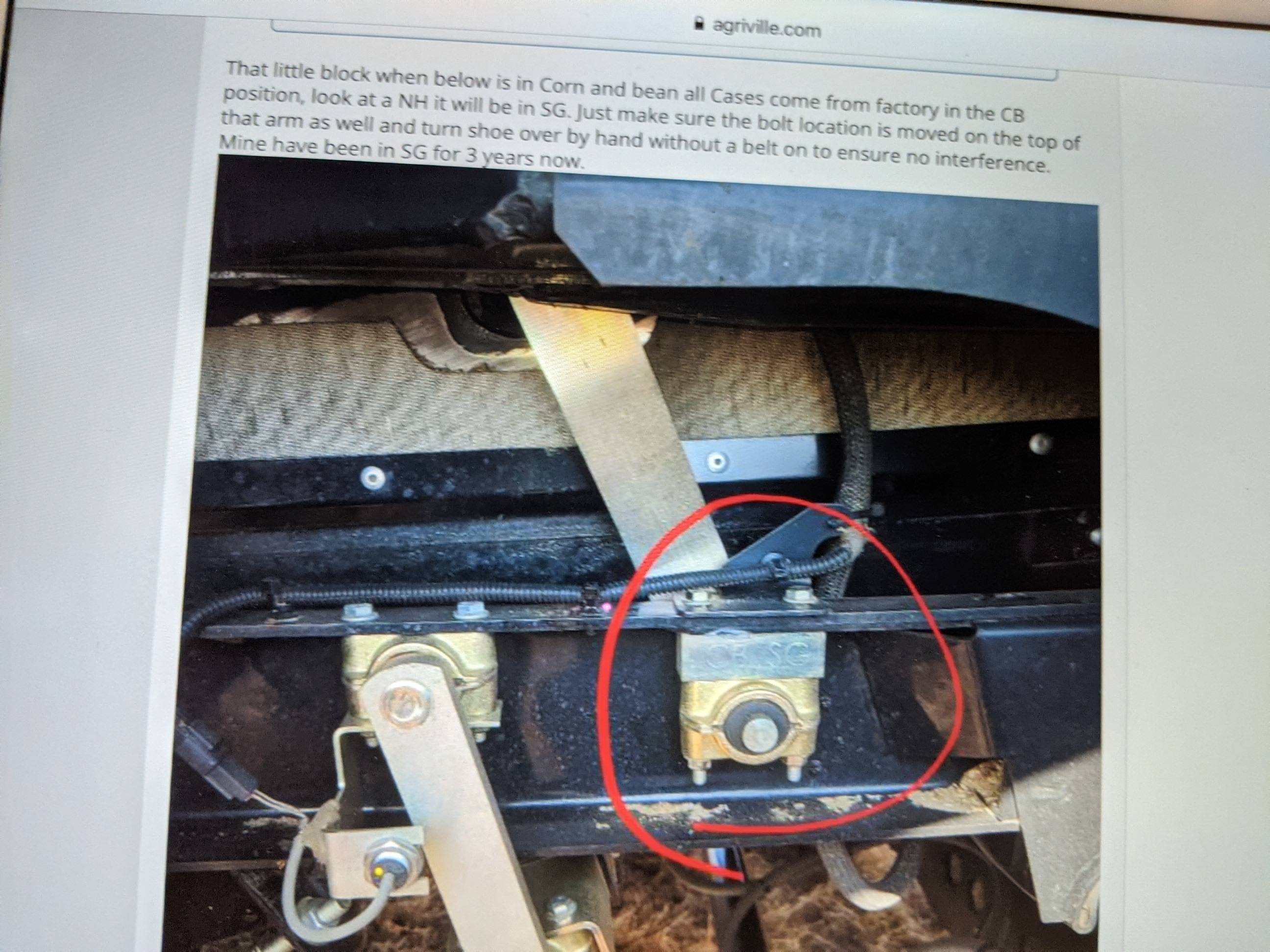

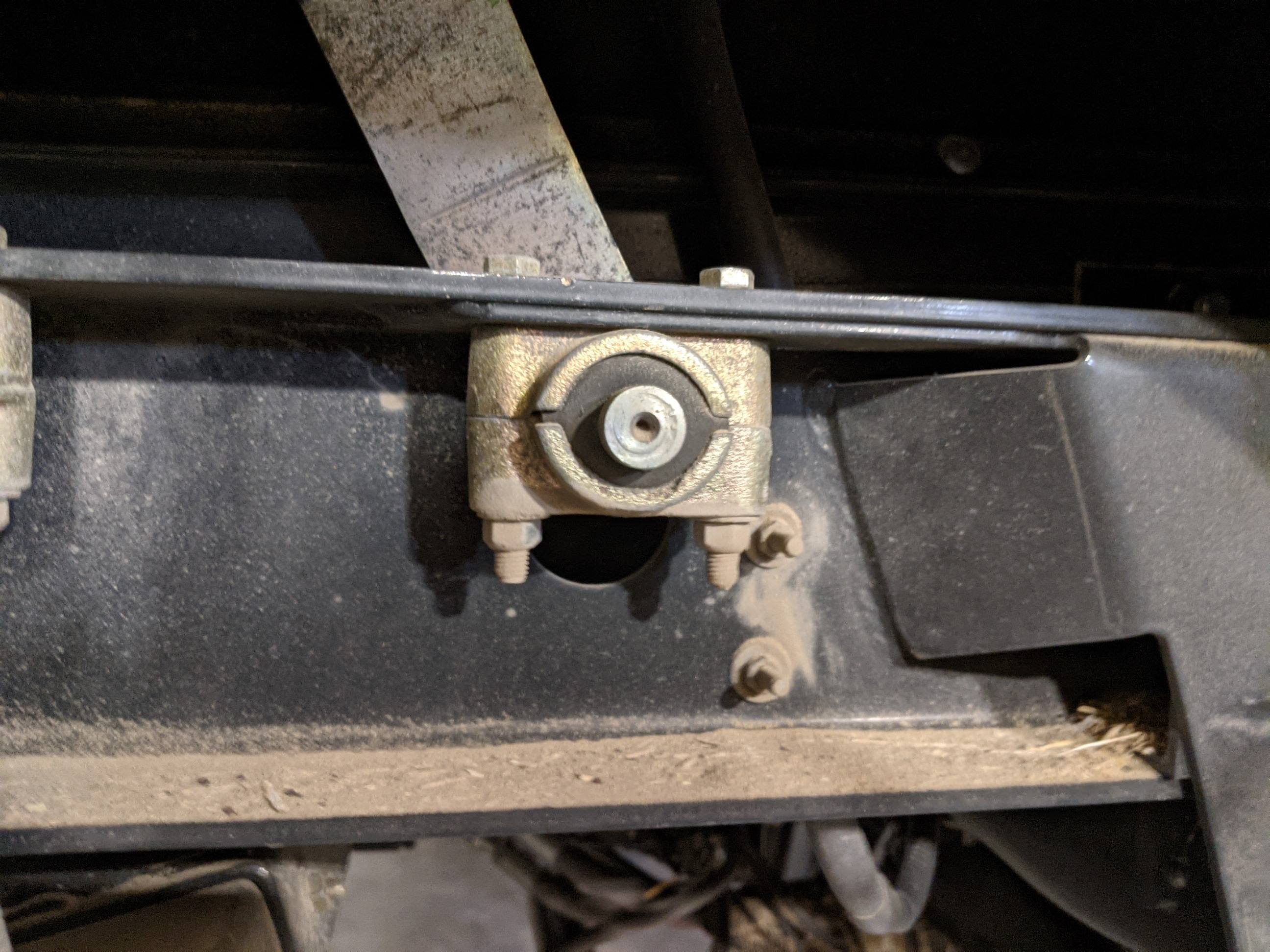

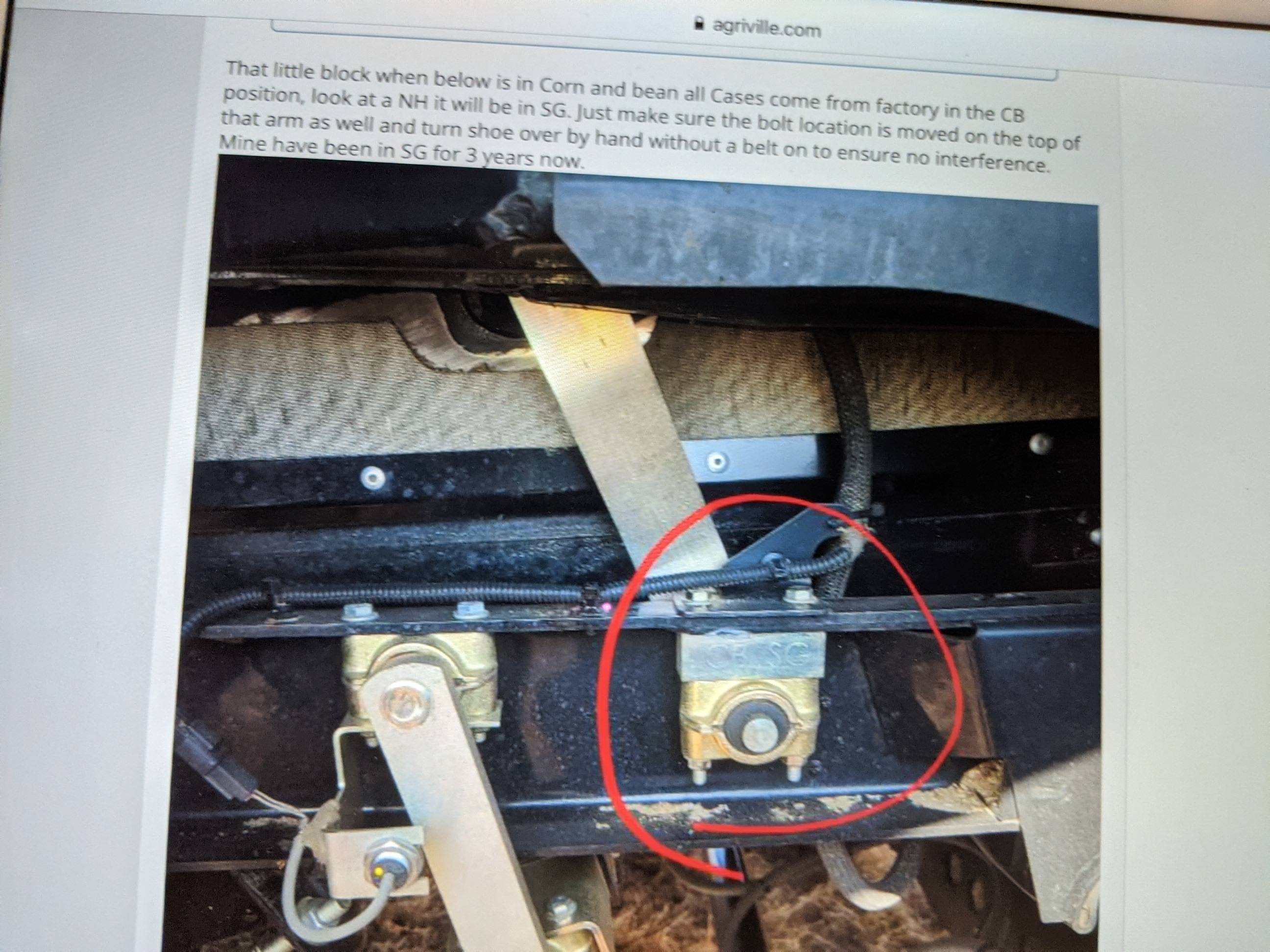

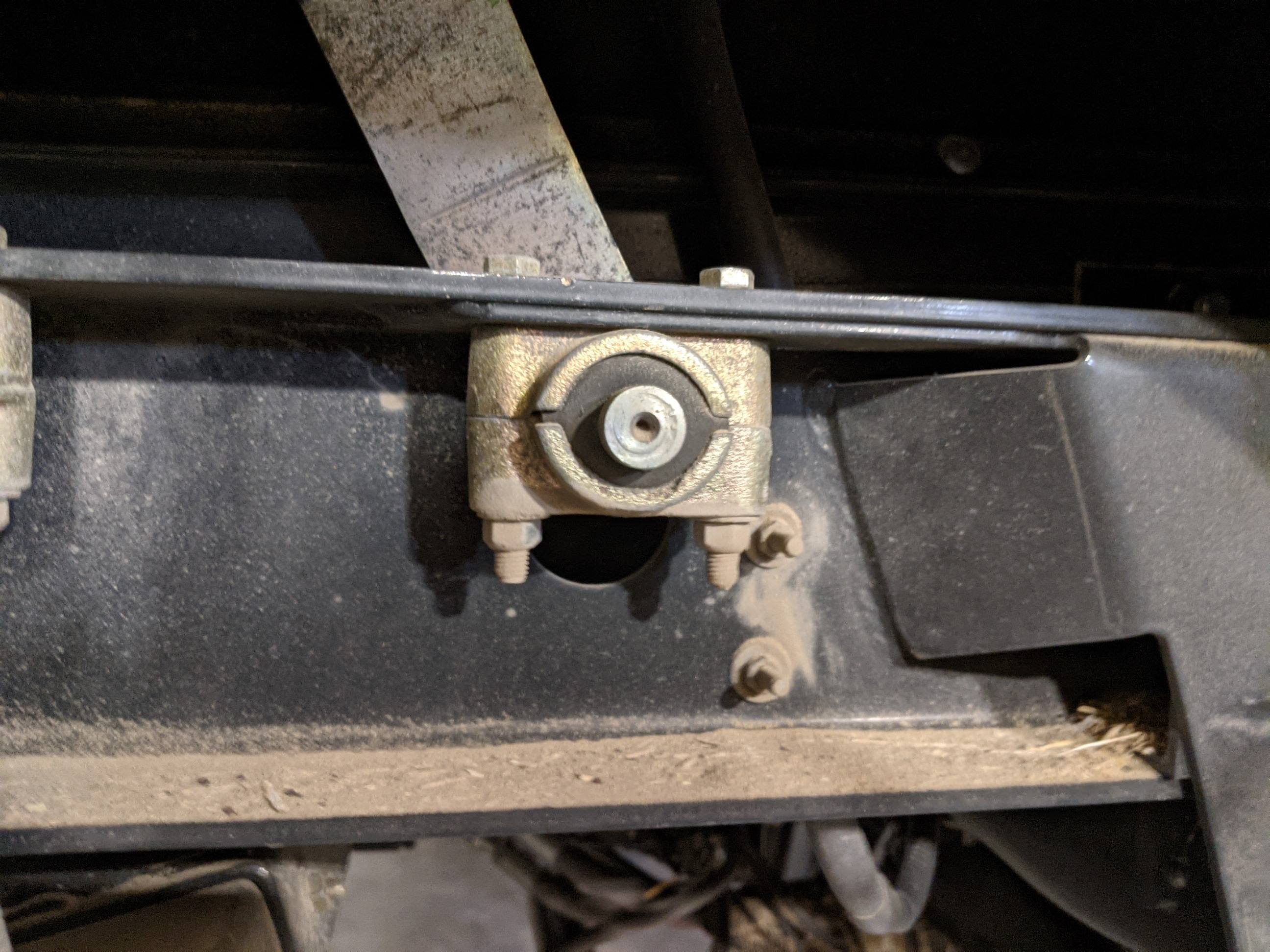

Instead of posting on the Friday report I'll start a new thread. I'm running a 9230, CR9080 and a 9.9 elevation. The 9230 and 9080 are on the S/B position and the 9.9 looks the same but with no block as posted by Biglentil, I'm assuming that the above arm connected to the bushing has 2nd hole higher on the arm or not? The 2nd pic is our 9.9 with no block so am assuming it's in the SB-C position.

Comment