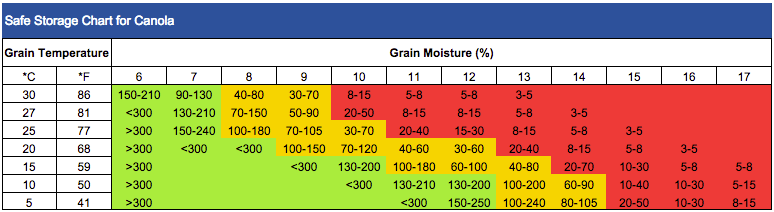

Monitoring non aeration bins full of dangerously damp canola. I've been turning when any point in the bin gets over 15 C. At that point there is a bit of clumping already. But I can't find any info on what temp is safe, anyone here have a number they use? Have 2 bins right now that have layer that is at 15C but has been stable for quite a while. Only 14' bins, one 6 ring, one 8 ring.

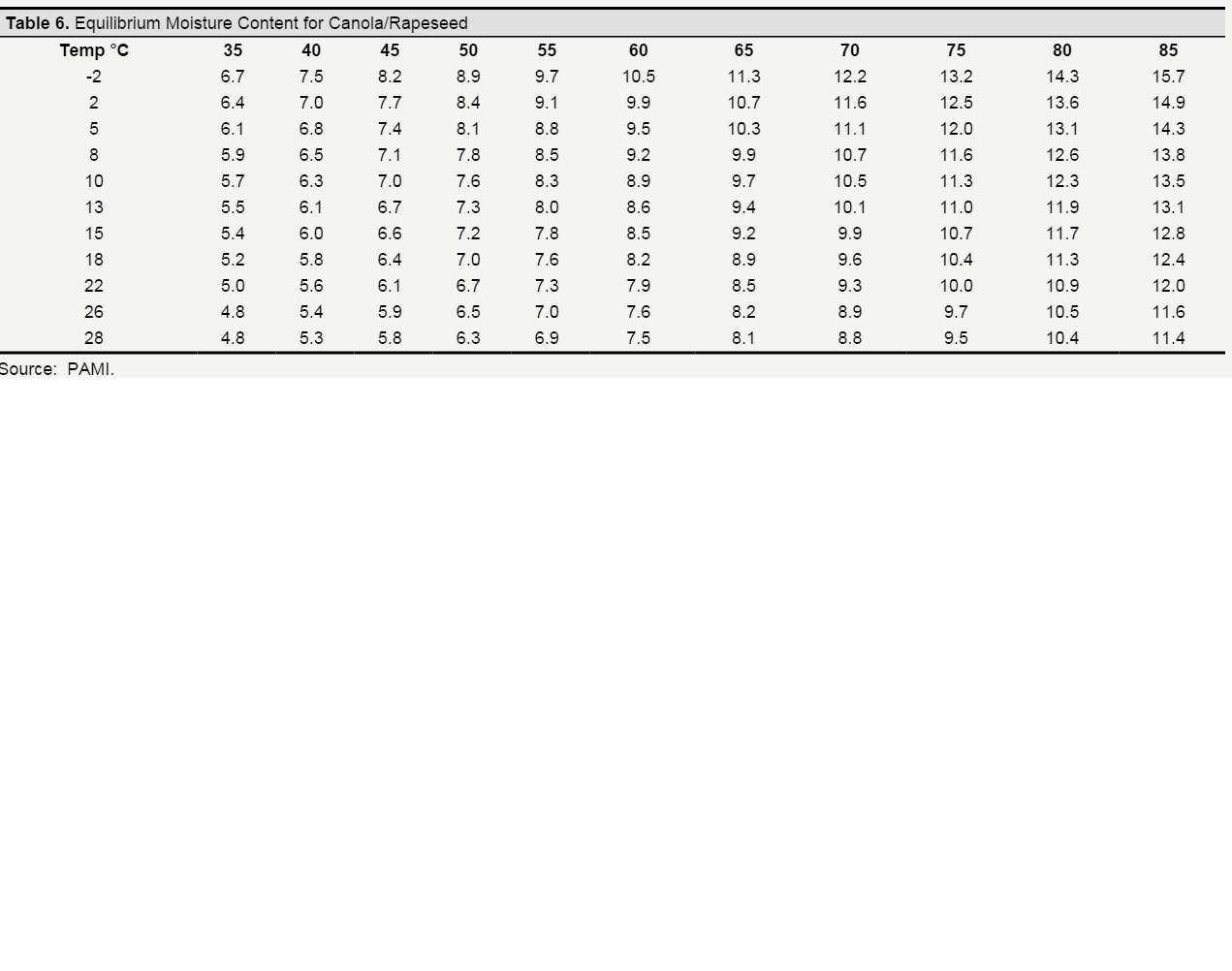

Also, I have most of the bins with air, and it safely frozen. Am I doing any good to keep pumping cold dry air in, or leave well enough alone and wait for warmer weather? I ran them steady for over a month, now just run them occasionally when it is really cold.

And apologies for using the marketing forum, but so does everyone else....

Also, I have most of the bins with air, and it safely frozen. Am I doing any good to keep pumping cold dry air in, or leave well enough alone and wait for warmer weather? I ran them steady for over a month, now just run them occasionally when it is really cold.

And apologies for using the marketing forum, but so does everyone else....

/URL]

/URL]

/URL]

/URL]

Comment